REPAIR AND IMPROVE INDUSTRIAL WASTEWATER TREATMENT PLANT (IWTP) (CP1711M&R) MARINE CORPS AIR STATION CHERRY POINT, NORTH CAROLINA

Biography

What Is ASME?

What Is RTP-1?

RTP-1 stands for Reinforced Thermoset Plastic, Specification 1, developed by ASME to provide a comprehensive standard for the fabrication of FRP tanks operating at or near atmospheric pressure (15 psig or less). It’s the gold standard for non-metallic tank construction and covers:

- Material Selection: Ensuring the correct resins, fibers, and liners are used based on the tank’s application.

- Design Criteria: Specifying wall thickness, corrosion allowance, and structural reinforcements.

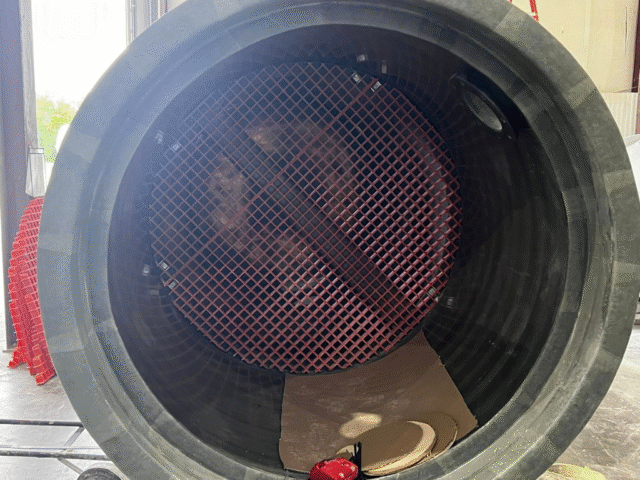

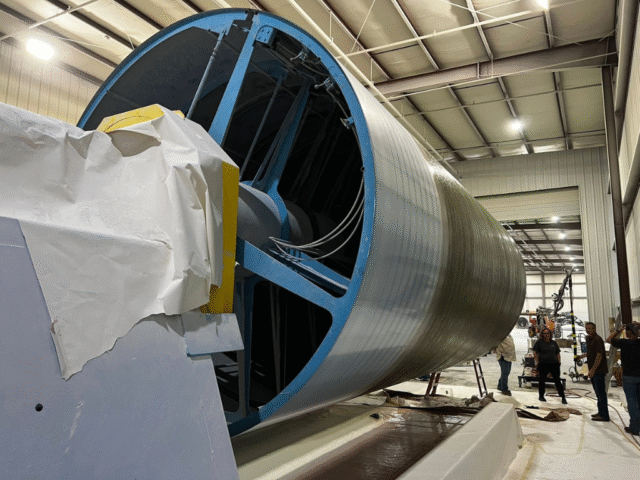

- Fabrication Processes: Detailing approved manufacturing methods like hand lay-up, filament winding, and chop spray-up.

- Inspection & Testing: Requiring hydrostatic testing, visual inspections, and documentation to guarantee every tank is built to perform.

Why Choose RTP-1 Certified Tanks?

Our Expertise

Custom-Engineered FRP Tanks

For a wide range of industries including chemical processing, water treatment, food and beverage, and more.

Turnkey Solutions

From design and fabrication to delivery and field installation.

Certified Fabrication

Tanks manufactured under strict ASME RTP-1 compliance.

Field Services

Inspections, repairs, retrofits, and re-certifications.

What Is ASME?

What Is RTP-1?

RTP-1 stands for Reinforced Thermoset Plastic, Specification 1, developed by ASME to provide a comprehensive standard for the fabrication of FRP tanks operating at or near atmospheric pressure (15 psig or less). It’s the gold standard for non-metallic tank construction and covers:

- Material Selection: Ensuring the correct resins, fibers, and liners are used based on the tank’s application.

- Design Criteria: Specifying wall thickness, corrosion allowance, and structural reinforcements.

- Fabrication Processes: Detailing approved manufacturing methods like hand lay-up, filament winding, and chop spray-up.

- Inspection & Testing: Requiring hydrostatic testing, visual inspections, and documentation to guarantee every tank is built to perform.

Why Choose RTP-1 Certified Tanks?

Our Expertise

Custom-Engineered FRP Tanks

For a wide range of industries including chemical processing, water treatment, food and beverage, and more.

Turnkey Solutions

From design and fabrication to delivery and field installation.

Certified Fabrication

Tanks manufactured under strict ASME RTP-1 compliance.

Field Services

Inspections, repairs, retrofits, and re-certifications.